Supply chain management was one of the factors that helped us out of the middle ages. Where would we be today without the tools and processes to manage the flow of goods and services or the ability to utilize specialistâs skills and resources far apart from another? Chances are, weâd still be raising our own food.

While I admit that I have days when I fantasize about this type of simplicity, I like my cushy life too much to give up on essentials like Starbucks coffee. Plus, my family would quickly starve if we had to rely on my farming skills. So, it is good that instead of farming and foraging, I work for a software company instead.

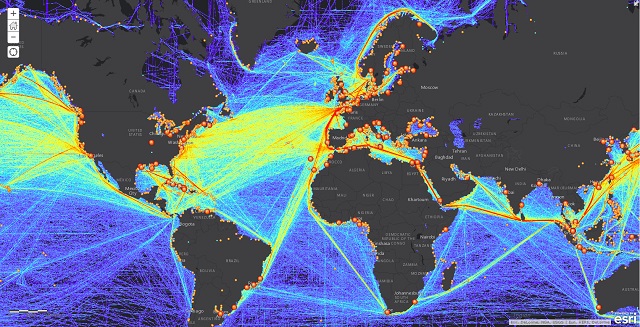

Today, the flow of goods in the world relies heavily on bits and bytes shared among the worldâs computers. Each day, software and computers control billions of dollars-worth of goods traded between countries. These goodsâanything from livestock and produce to mobile phones and coffee beansâtravel from farms and assembly plants to stores by truck, rail, air, and ship. Â Supply chains link the worldâs population tightly together; all our lives depend increasingly on timely and smooth operations and careful supply chain management.

PIMBYâThereâs a âPort in My Back Yardâ

Understanding the role supply chain management plays is critical. In this case, seeing is believing and believe me, knowing where infrastructure is located can make or break the supply chain. Logistics centers are the powerhouses of the supply chain. Two of the largest container ports in the US are located right here in Southern California, about an hourâs drive from Esri headquarters: the Port of Long Beach and the Port of Los Angeles.

Not only do these ports comprise an important regional hub, they are also a big deal to the rest of the country. From here, most Asian goods get unloaded and distributed into the US supply chain. Last year 14.6 million shipping containers passed through these ports. In fact, 40 percent of all goods imported into the US last year came from these two ports, right in my backyard. Any disruption of the regional supply chain impacts the economy not only regionally but nationally and perhaps even beyond.

Does a global supply chain have regional affects?

Even though a majority of the goods that pass through go to other parts of the country, these ports have a huge impact on the region. The Port of Long Beach, for example, supports more than 30,000 jobs in Long Beach alone, and 316,000 jobs throughout Southern California.

The ports directly serve the Inland Empire (IE), once known for being the first to burst in the housing bubble. What helped it rebound? The logistics industry. The IE handles about 75 percent of the goods that are imported through these ports. Truck drivers, inventory managers, and warehouse workers are growing the economy in the IE at a rate of one in five of all new jobs added in the area.

A Perfect Storm in the Retail Revolution

Why is this area doing so well in supply chain? It has everything to do with geography. Two major international airports are located here, along with thousands of miles of roads and highways, as well as rail lines. The higher transport costs shippers incur by driving goods 60 miles inland from the ports is offset by lower real-estate and labor costs in Riverside and San Bernardino Counties.

And with land so much cheaper here than in counties to the west, such as Los Angeles and Orange, mega warehouses and distribution centers for big named big-box and online retailers including Amazon, , Best Buy, Home Depot, Nestle, Nike, Nordstrom, and Samsung, Â are sprouting up. One of the U.S.âs biggest warehousesâthe Sketchers Distribution center, which is 1.82 million square feet, or enough to fit more than 30 football fieldsâis located here in Southern California.

How do we manage a sustainable supply chain?

Well managed supply chains are critical for our economy. Because of the volume of shipments and risks involved (weather, natural catastrophes, political, and theft to name a few), effective supply chain management is very complex with the demand to analyze a lot of data.

Complex data becomes intuitively understandable when we visualize it properly. Our brains evolved and are trained to recognize patternsâone of the key reasons why maps are so successful in communicating complex scenarios.  GIS is the perfect toolset to visualize business complexity using advanced mapping and to provide analysis tools to help us understand risk and supply chain efficiency.

Esri is teaming up with industry experts and academics to help identify needs, discuss potential research, and engage in the needs of supply chain organizations in the Southern California area. We are working together to address how to run such a complex network of production, storage, and transportation as efficiently as possible.

GIS for a Smooth Supply Chain

Tracking shipments and containers in real-time as well as seeing and predicting traffic and weather helps us to use our resources wisely and keep the supply chains well-oiled for smooth operations. Modeling business interruptions help us understand effects and quickly find work-arounds. Optimizing truck routes and trailers cuts down on emissions and pollutants. As a logistics leader at a Southern California Supply Chain conference just noted: âWithout trucks weâd be sitting here naked without tablecloths and tables.â

There are a myriad of ways that GIS helps maintain a sustainable supply chain. We canât afford not to use the tools we have available to make a difference in our world.

insider